Gadget

Well-Known Member

- Joined

- Jan 13, 2007

- Messages

- 10,932

- Reaction score

- 173

I have a 1GR block at Darton getting sleeved. Lots of people are asking me about this and how it is done and I think some pictures will make this make more sense.

This is the first 1GR block that Darton has done. They have done the 2GR and some other Toyota blocks, but not this one yet. They had hoped one of the cylinders sleeves from the other engines would fit, but no such luck. They have to make a complete new design.

The first step is to get a block and cut it into slices and then scan the slices to get the interior of the block design into the CAD enviroment. From there they develop the CNC program for cutting out the old cylinders and designing the new ones to press in to replace them. Our friend Torspd furnished one of his used blocks for Darton to cut up.

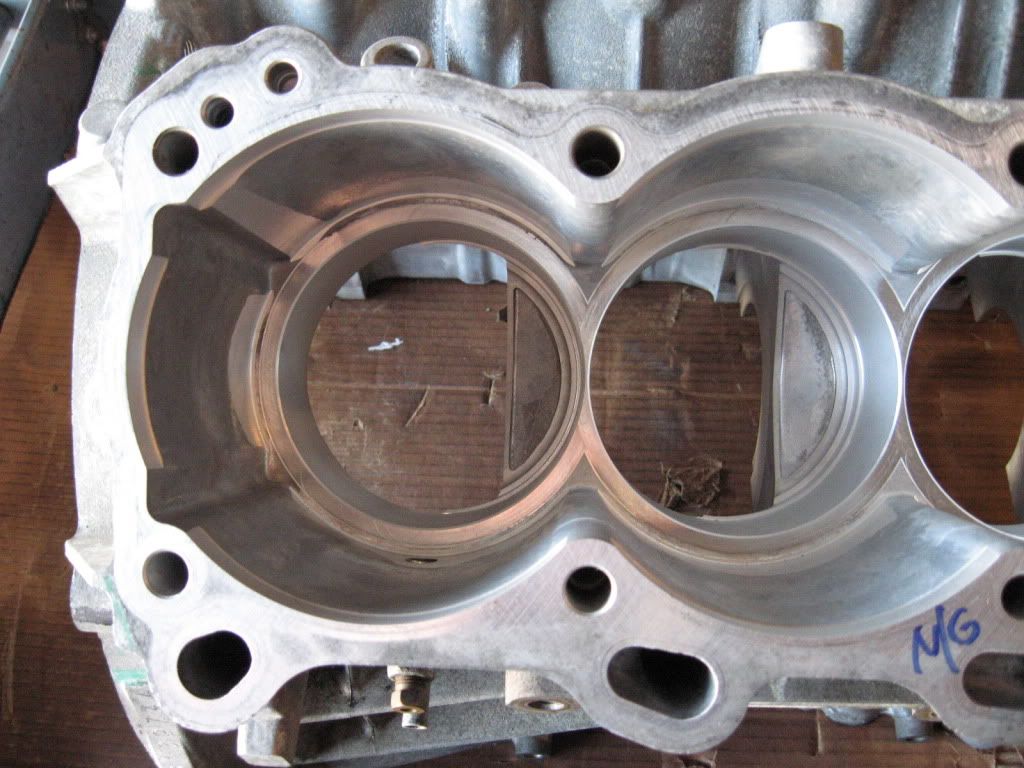

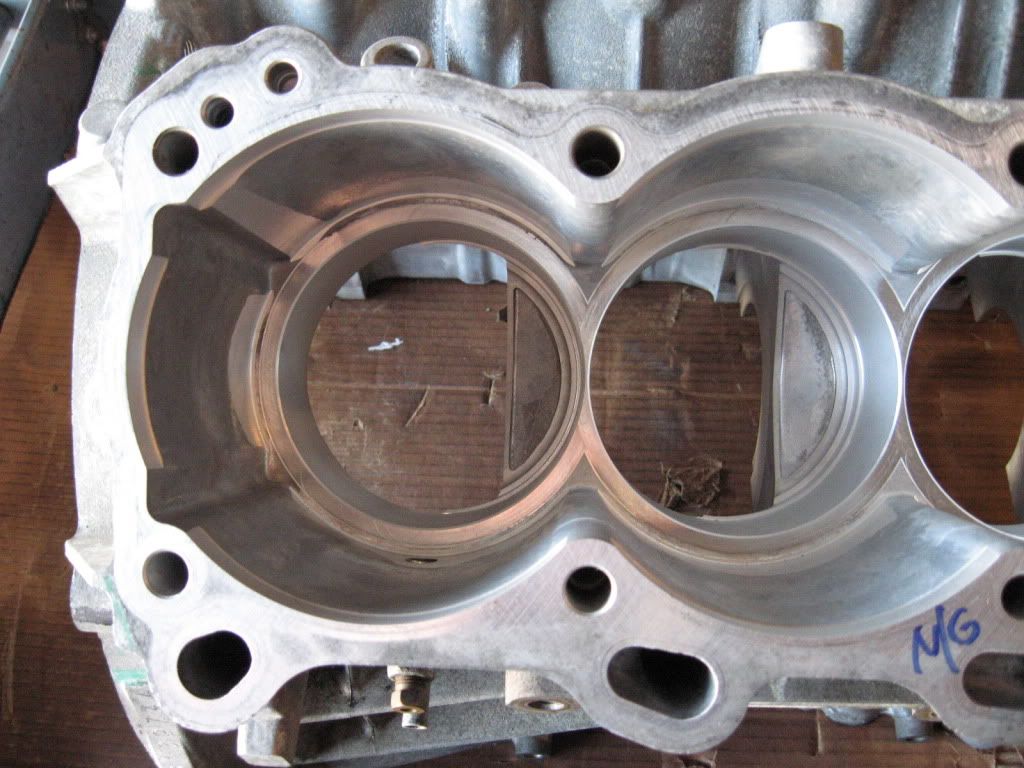

Here is a picture of the stock engine block:

If you look very closely you can see the slight color change in the cylinder top. The steel liner is very thin and the outside is the aluminum.

On the 1GR the very thin steel sleeves are cast into place when the aluminum block is cast. This block is an open deck design, typical of most modern engines today. The upper portions of the cylinder is not supported by the engine block. This is fine for N/A applications, but when converted to forced induction the upper portions of the cylinder can wiggle and move just a little bit and break the seal at the head gasket. This can be from the normal elastic action of the metal from the increased cylinder pressures or the dramatic increase in cylinder pressures if detonation occurs. The walls of the cylinders are very thin and there have been reports of the cylinders splitting open like a banana peal.

The first step is the stock cylinders are cut away using a CNC machine.

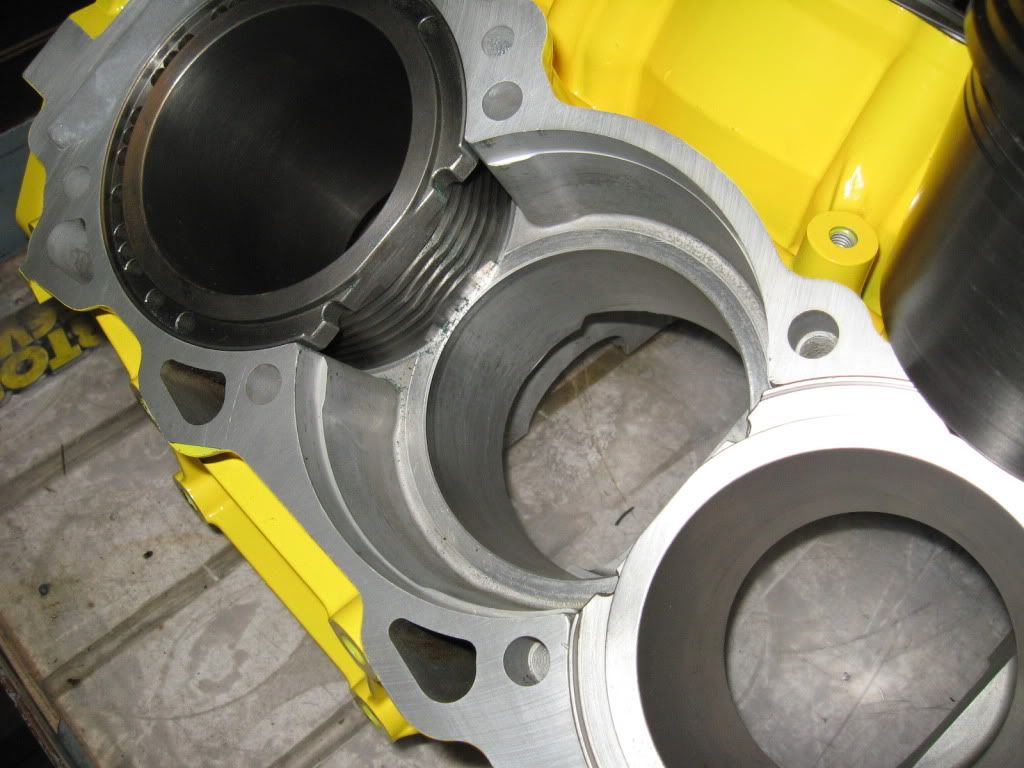

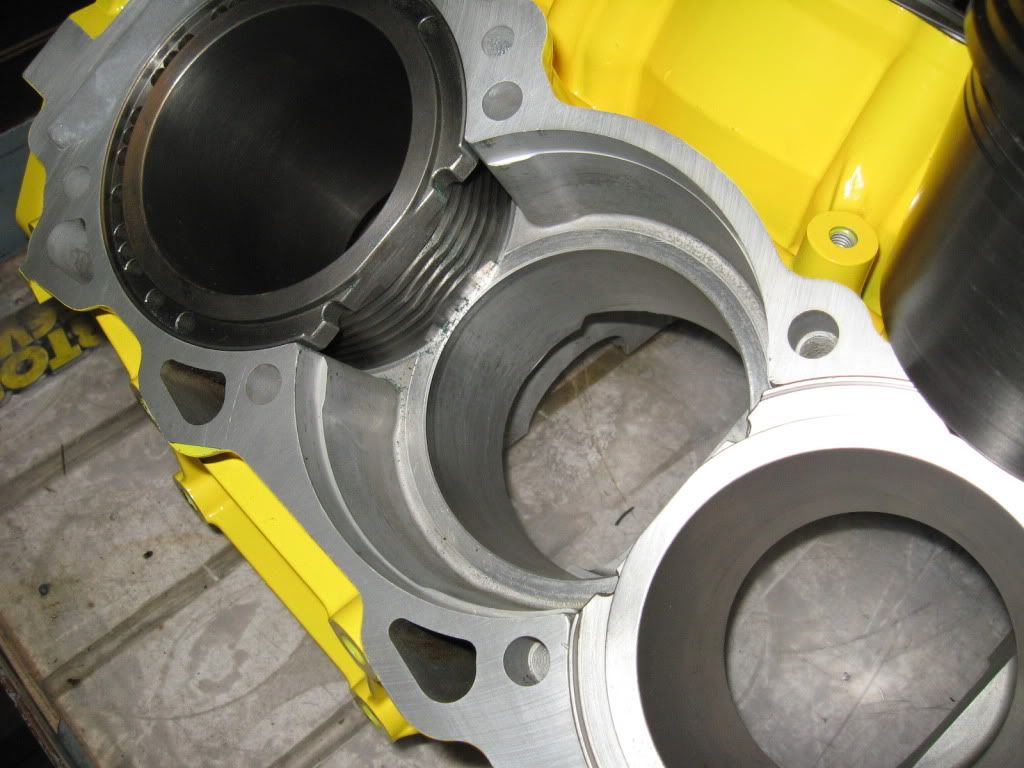

The next step is the new sleeve is pressed into the block.

The block is then decked and ready for the cylinders to be honed to the correct size for the new pistons. This is a Nissan VG35 block. You will notice that is now a closed deck design and the tops of the cylinders are now supported to the engine block for one very solid assembly.

There you are. If you have any more questions give John at Darton Sleeves a call and I am sure he can answer any questions you have.

My block should be done in a few weeks then I am going to have APR assemble the rest of the engine for me with the pistons and rods I got from TTC and some other cool parts and trick work.

Gadget

This is the first 1GR block that Darton has done. They have done the 2GR and some other Toyota blocks, but not this one yet. They had hoped one of the cylinders sleeves from the other engines would fit, but no such luck. They have to make a complete new design.

The first step is to get a block and cut it into slices and then scan the slices to get the interior of the block design into the CAD enviroment. From there they develop the CNC program for cutting out the old cylinders and designing the new ones to press in to replace them. Our friend Torspd furnished one of his used blocks for Darton to cut up.

Here is a picture of the stock engine block:

If you look very closely you can see the slight color change in the cylinder top. The steel liner is very thin and the outside is the aluminum.

On the 1GR the very thin steel sleeves are cast into place when the aluminum block is cast. This block is an open deck design, typical of most modern engines today. The upper portions of the cylinder is not supported by the engine block. This is fine for N/A applications, but when converted to forced induction the upper portions of the cylinder can wiggle and move just a little bit and break the seal at the head gasket. This can be from the normal elastic action of the metal from the increased cylinder pressures or the dramatic increase in cylinder pressures if detonation occurs. The walls of the cylinders are very thin and there have been reports of the cylinders splitting open like a banana peal.

The first step is the stock cylinders are cut away using a CNC machine.

The next step is the new sleeve is pressed into the block.

The block is then decked and ready for the cylinders to be honed to the correct size for the new pistons. This is a Nissan VG35 block. You will notice that is now a closed deck design and the tops of the cylinders are now supported to the engine block for one very solid assembly.

There you are. If you have any more questions give John at Darton Sleeves a call and I am sure he can answer any questions you have.

My block should be done in a few weeks then I am going to have APR assemble the rest of the engine for me with the pistons and rods I got from TTC and some other cool parts and trick work.

Gadget

Last edited: