Coupe

Active Member

- Joined

- Dec 31, 2007

- Messages

- 6,871

- Reaction score

- 15

im interested in the milled out pan also coupe

O.K., maybe three (3) then.

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!im interested in the milled out pan also coupe

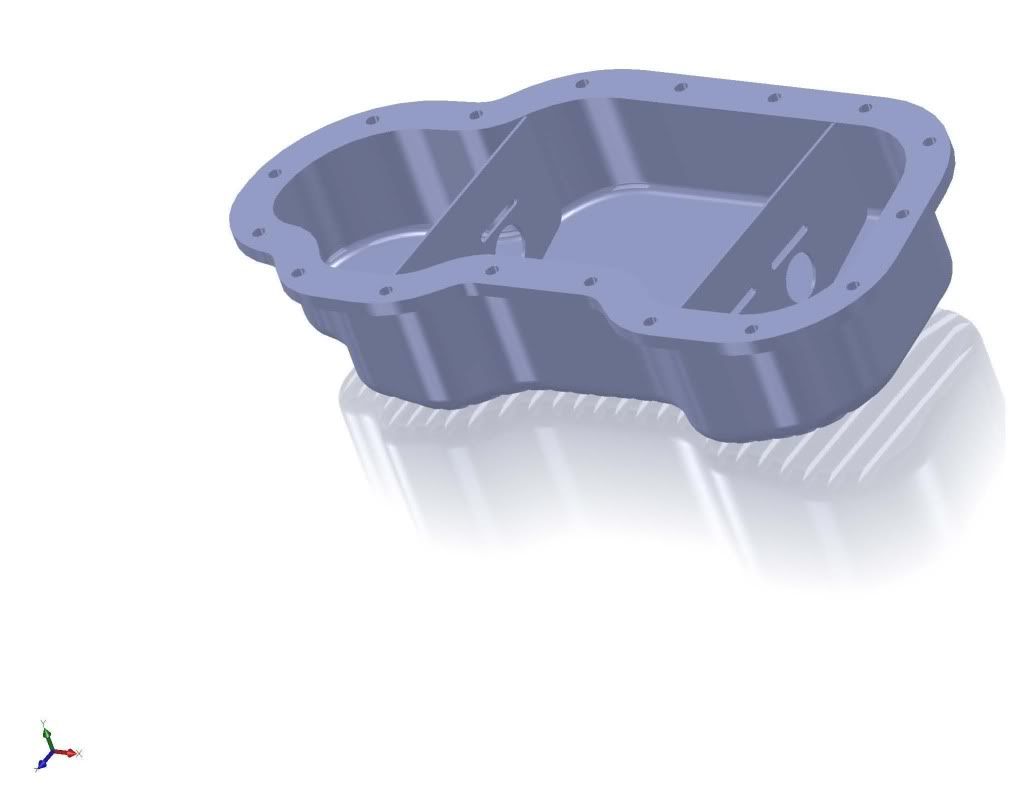

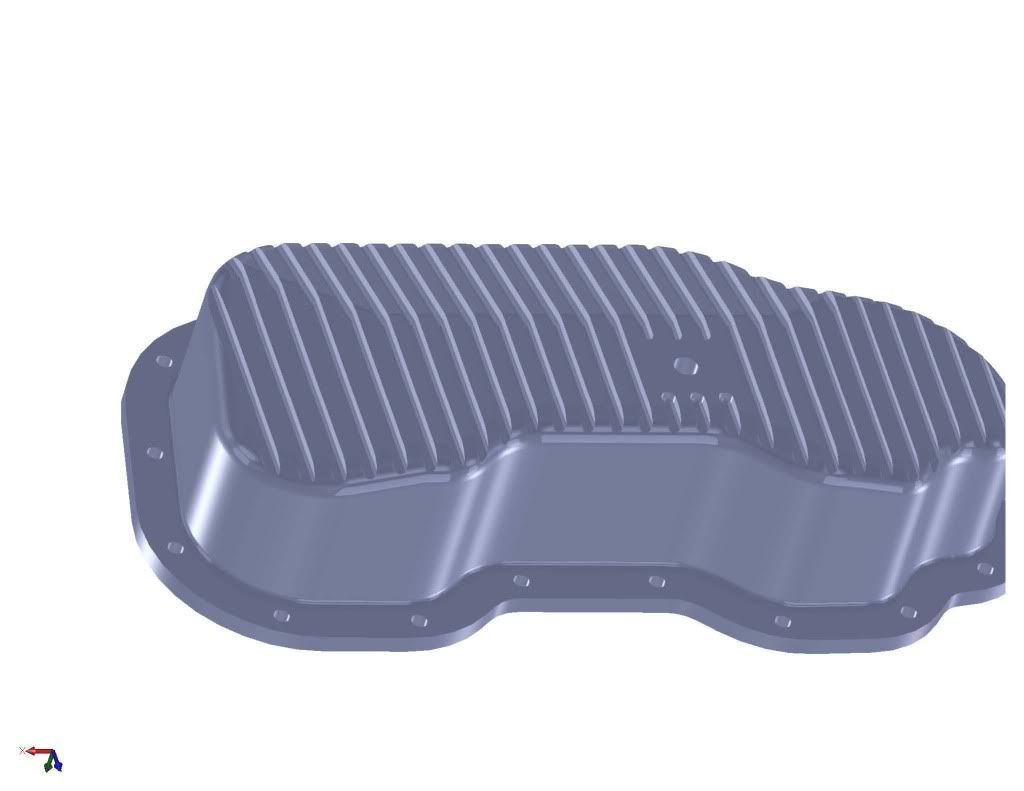

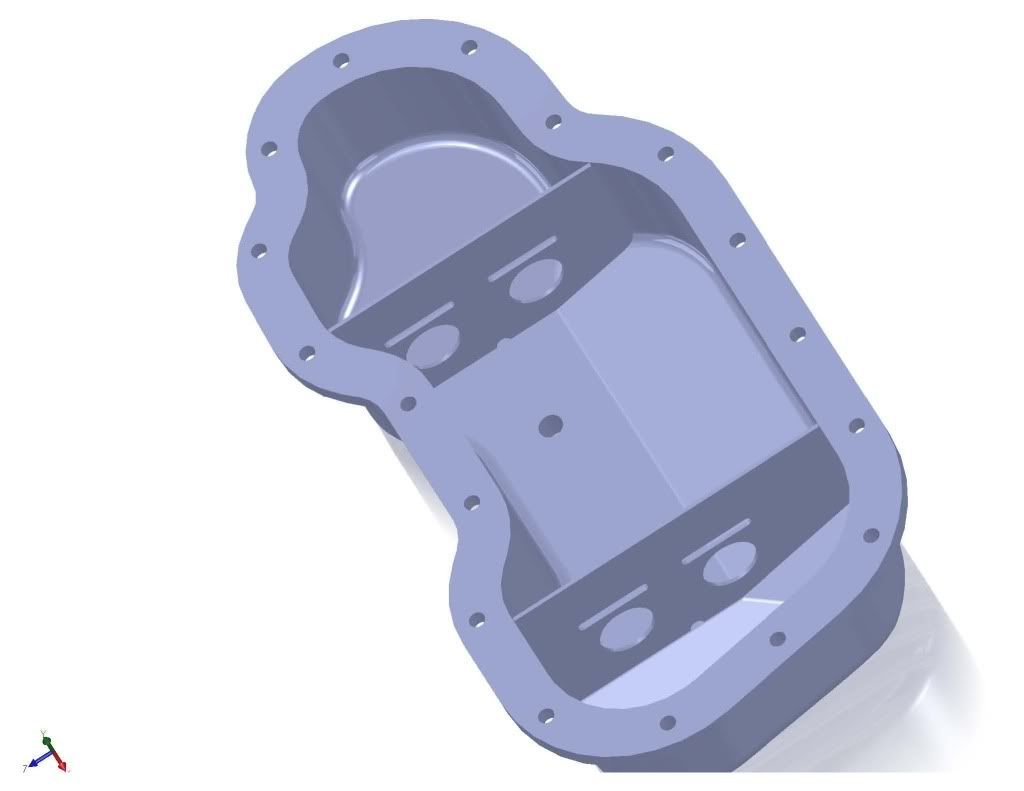

This could be cast out of aluminum.

I have done a couple of cast parts recently and it will be very good for that. You can improve on the shape and even droop it more at the point of the sump pickup and make it even deeper.

After casting the mating surface would have to be machined.

The spacer for the pickup could be cast also, then a finish machine on both sides.

Cost per piece would be cheap, but there would be some design and tooling costs up front, in the end it could be made to fit better and make it even deeper.

G

Any reason option 2 can't have an aluminum spacer?

any updates yet coupe

What about machining just the baffles for the stock oil pan. Then selling those to people to have reputable local welders to weld them in to their stock oil pan? And maybe sell them an oil tube extension too? This would keep machine costs and time to a minimum, less liability for you, and a simple solution to a basic problem. You would definitely increase the number of sales and it might actually be in descent price range.

You are correct.Originally Posted by Gadget

This could be cast out of aluminum.

I have done a couple of cast parts recently and it will be very good for that. You can improve on the shape and even droop it more at the point of the sump pickup and make it even deeper.

After casting the mating surface would have to be machined.

The spacer for the pickup could be cast also, then a finish machine on both sides.

Cost per piece would be cheap, but there would be some design and tooling costs up front, in the end it could be made to fit better and make it even deeper.

G

I would be concerned about the part count required to do this and whether demand would support it.

I am good at getting a few custom parts made. Large quantity runs are another thing.