sdxrunner619

Active Member

- Joined

- Jan 20, 2010

- Messages

- 3,836

- Reaction score

- 7

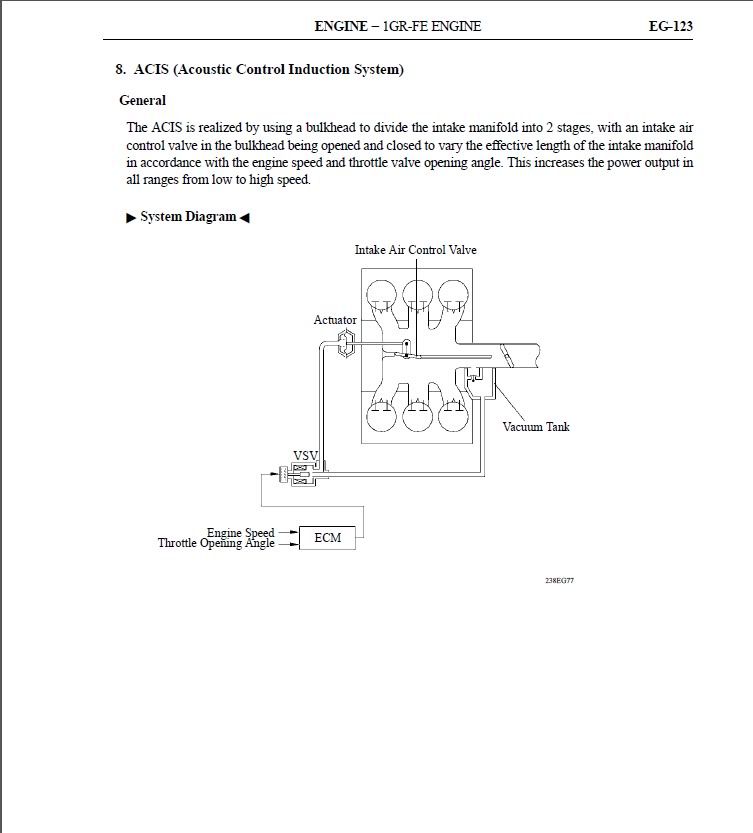

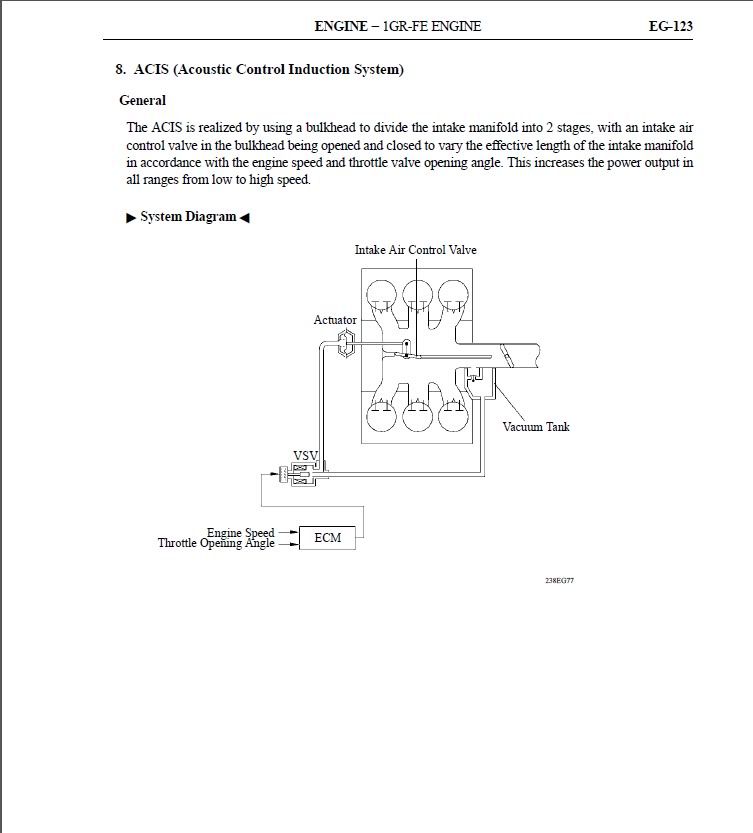

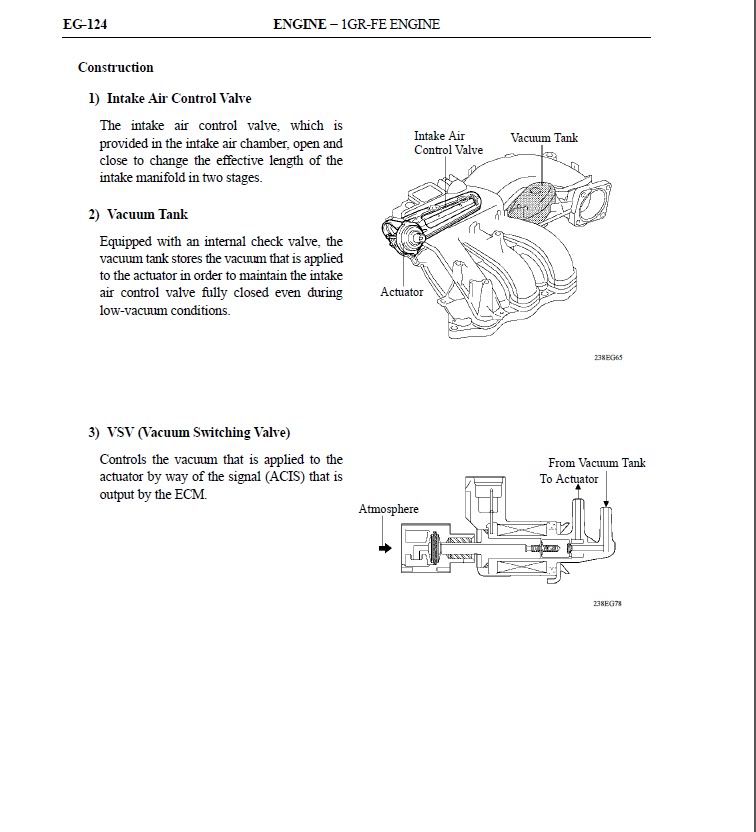

Most people think our intake plenum is just a funny looking piece of plastic used for directing air into our motor, and that their is some sort of actuator on the back that does something or another....Here is what it really does, according to Toyota:

Remember, the whole variable length runner theory (ACIS and other non Toyota app) is designed for N/A applications...not forced induction

When my motor blew back in September, i couldn't for the life of me figure out what happened until is shoved a Borescope inside my plenum and found a something missing...A SCREW that holds the "bulkhead" or butterfly valve onto the shaft worked its way lose and went through my motor...i thought it just vibrated lose, but when i cut the actual valve out of my intake, i found this... (INB4 toe-thumb jokes...no, The all-mighty TOE-SPD was not helping me with this...):rofl::rofl::rofl:

Missing screw....But wait, THERE'S MORE!!!!! turn out, the screw didn't vibrate lose, THE SHAFT BROKE!!!

Now...what would cause this shaft to break...IDK...lets see, fatigue...age...rapid opening and closing...maybe it was miss-handled...maybe positive PRESSURE???? At the time, i was rocking a URD MRK-1, stage 3, and the plenum/motor itself had about 138k miles on it...so, approx 9psi being shoved into it. The Bulkhead (valve) itseslf is housed in a plastic "case" and is actuated via a metal shaft, controlled by the shaft and vacuum diaphragm below... The only thing in the picture above that is metal is the valve, shaft and screw...the rest of the assy. is plastic.

Cut-away of the plenum, with the bulkhead removed...

Now, this ACIS system was not designed to have air SHOVED into/past the bulkhead/door, just direct it. I cant help but wonder if having positive manifold pressure on it caused it to fail...or if it was just a freak accident, and the part failed for no reason. :dontknow: I do know that the screw went into the motor while doing some figure 8's, so it was most likely under-boost when the screw went through, whether or not the valve was open or closed, i cant say.

So to recap, you guys/I had/have positive manifold pressure going past a bulkhead housed in a plastic case, with a weak shaft and all of it is housed in a plastic plenum...:ahhhhh: People all ways talk about what these plenums can take before they split part, similar to G35's...(if i recall, 15psi is the DANGER ZONE for them)...Nobody really knows how much boost these intakes can take before they fail by cracking...or damage the ACIS components like in my case.

Now, reason im even bother posting this is for you Turbo and URD S/C guys to ponder about what position that valve should be in...

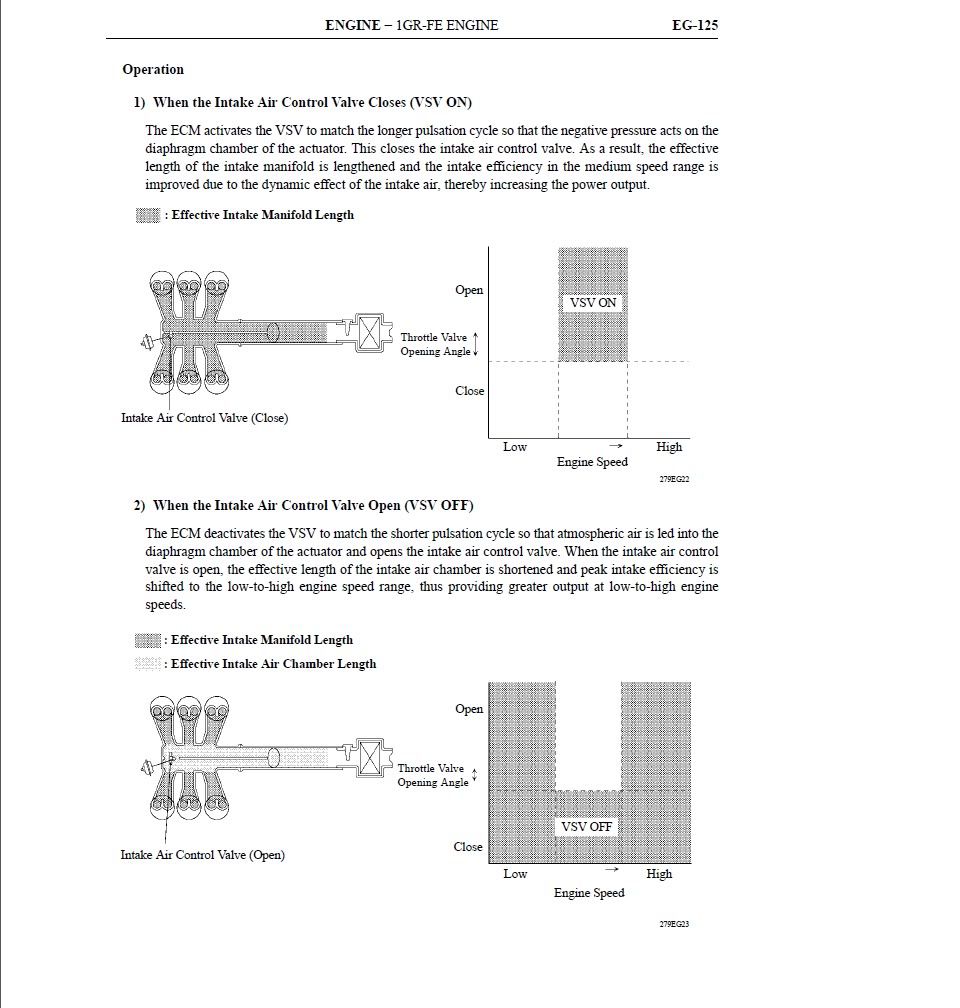

NO VACUUM on the diaphragm will yield CLOSED valve, (long runner mode).

VACUUM to the diaphragm will open it. (short runner mode)

The vacuum tank is designed to store vacuum so that the ECU can open or close the valve with or with out actual mani vacuum...

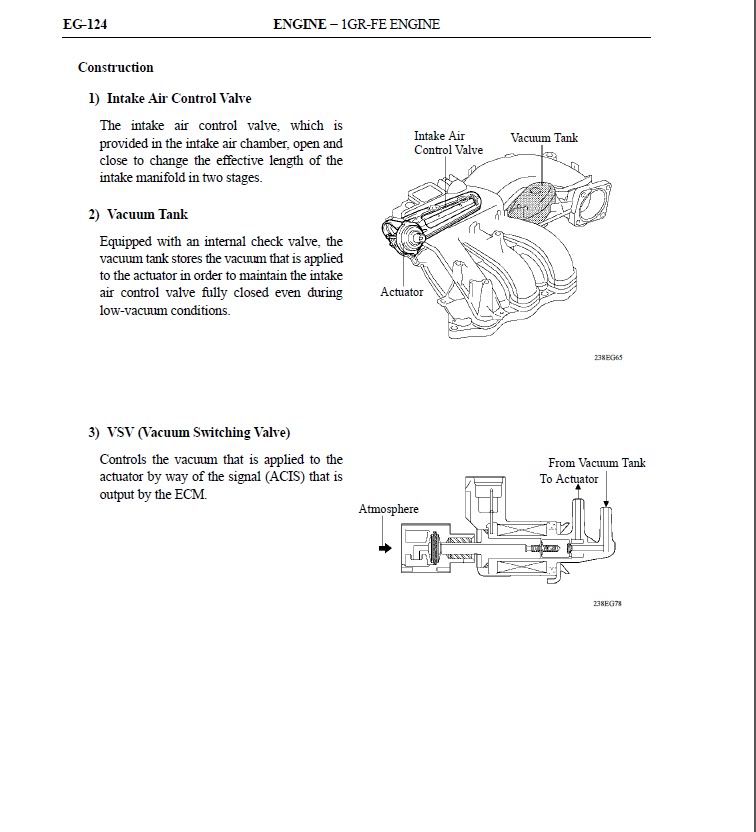

"Equipped with an internal check valve, the

vacuum tank stores the vacuum that is applied

to the actuator in order to maintain the intake

air control valve fully closed even during

low-vacuum conditions"

The whole point of this ramble was to inform the general public about whats actually going on inside our plenums when air is being routed about according to the ECU's programming...and that the whole system was never designed to have positive manifold pressure being acted upon it....

I AM NOT BLAMING THE URD MRK-1 IN ANYWAY FOR MY MOTOR FAILING:top:

I switched out for TRD because i was paranoid about it happening again and i hated the power delivery of the Rotrex blowers in general, and knew that it was not going to work with what i wanted to do with my truck...and as far as i can tell, nobody knows for sure if the MRK-1 (or positive mani pressure in general) was the cause of my motors demise... as even the F/I "experts" cant say for sure how much PSI wil cause the manifolds fail (split from sheer PSI)...let alone the ACIS failing from "unusual forces acting on it"

With that being said, i just wanted to let the public know my POV on the subject and leave this thread open for debate on what to do about the ACIS and F/I (non TRD F/I) on our manifolds will do...

The TRD s/c doesn't have this system so this doesn't pertain to the TRD S/C...this should be oblivious as the TRD blower mounts in place of the factory plastic intake...:top: Figure i'd throw that out their...

~~~

Few starter questions for Gadget, as he seems to be on the leading edge of safety s/c these motors. :adore:

1. Have you tried doing dyno runs with the ACIS system open or closed?

2. Can the X-1 or UCON EMS be used to control the ACIS system to BENEFIT the power band of a URD S/C truck?

~~~

Please, lets not turn this into a TRD vs URD debate...this has to do with positive mani pressure in general, on our OEM intake plenums, not about what makes more power or gets your **** sucked faster.... :top:

Remember, the whole variable length runner theory (ACIS and other non Toyota app) is designed for N/A applications...not forced induction

When my motor blew back in September, i couldn't for the life of me figure out what happened until is shoved a Borescope inside my plenum and found a something missing...A SCREW that holds the "bulkhead" or butterfly valve onto the shaft worked its way lose and went through my motor...i thought it just vibrated lose, but when i cut the actual valve out of my intake, i found this... (INB4 toe-thumb jokes...no, The all-mighty TOE-SPD was not helping me with this...):rofl::rofl::rofl:

Missing screw....But wait, THERE'S MORE!!!!! turn out, the screw didn't vibrate lose, THE SHAFT BROKE!!!

Now...what would cause this shaft to break...IDK...lets see, fatigue...age...rapid opening and closing...maybe it was miss-handled...maybe positive PRESSURE???? At the time, i was rocking a URD MRK-1, stage 3, and the plenum/motor itself had about 138k miles on it...so, approx 9psi being shoved into it. The Bulkhead (valve) itseslf is housed in a plastic "case" and is actuated via a metal shaft, controlled by the shaft and vacuum diaphragm below... The only thing in the picture above that is metal is the valve, shaft and screw...the rest of the assy. is plastic.

Cut-away of the plenum, with the bulkhead removed...

Now, this ACIS system was not designed to have air SHOVED into/past the bulkhead/door, just direct it. I cant help but wonder if having positive manifold pressure on it caused it to fail...or if it was just a freak accident, and the part failed for no reason. :dontknow: I do know that the screw went into the motor while doing some figure 8's, so it was most likely under-boost when the screw went through, whether or not the valve was open or closed, i cant say.

So to recap, you guys/I had/have positive manifold pressure going past a bulkhead housed in a plastic case, with a weak shaft and all of it is housed in a plastic plenum...:ahhhhh: People all ways talk about what these plenums can take before they split part, similar to G35's...(if i recall, 15psi is the DANGER ZONE for them)...Nobody really knows how much boost these intakes can take before they fail by cracking...or damage the ACIS components like in my case.

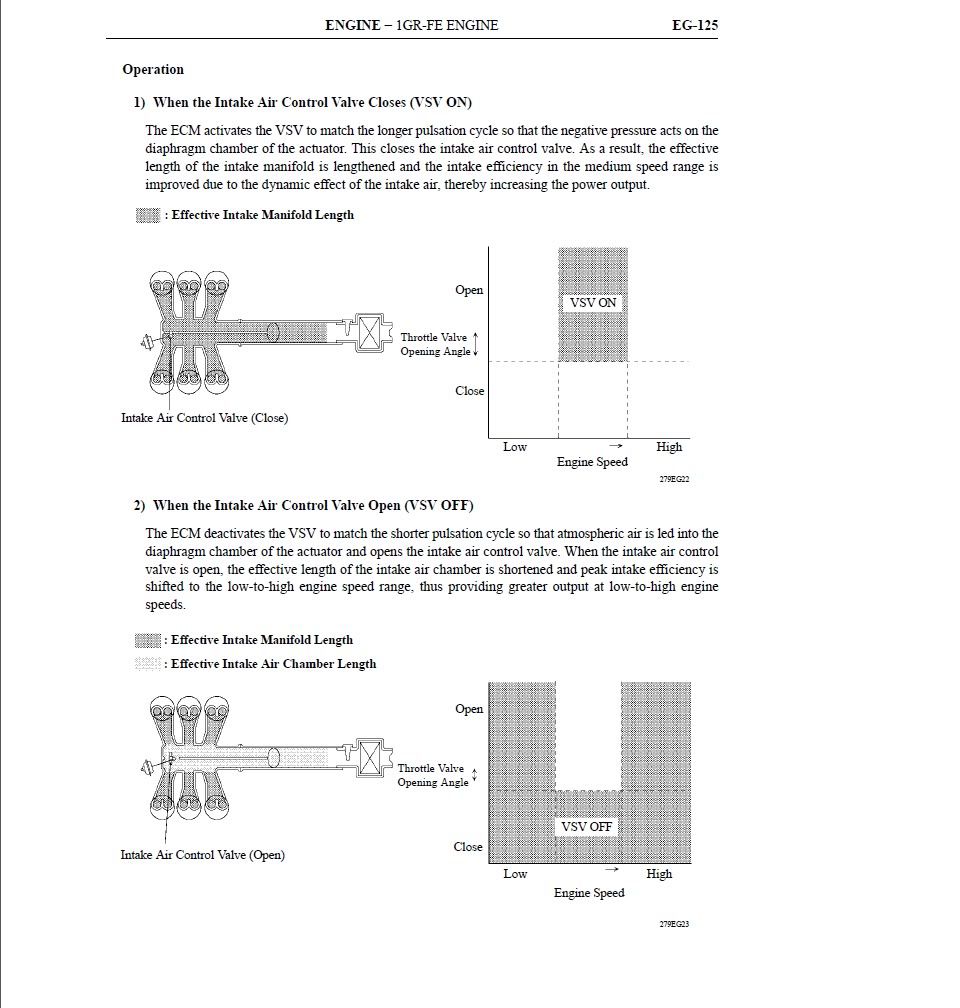

Now, reason im even bother posting this is for you Turbo and URD S/C guys to ponder about what position that valve should be in...

- Question #1, On a Turbo or URD s/c truck, is having it closed impeding on the flow of air to some extent and actually sapping power, or vise versa? I'm thinking a dyno experiment is in order..Two back to back pulls, one with the valve open, and one with it closed...Think about the TRD guys who pay big bucks to have their intake tracts/manifolds ported and cleaned up of any restrictions or bottle necks, to pick up a few more G/s, and in turn more HP....

So if removing small amounts of metal from around the TRD s/c intake and intake mani pick up some HP...what kind of flow does a 2x6" flap being slammed shut or opened in the Manifold do to peak G/S/HP????:hmmmm2::ahhhhh:

NO VACUUM on the diaphragm will yield CLOSED valve, (long runner mode).

VACUUM to the diaphragm will open it. (short runner mode)

The vacuum tank is designed to store vacuum so that the ECU can open or close the valve with or with out actual mani vacuum...

"Equipped with an internal check valve, the

vacuum tank stores the vacuum that is applied

to the actuator in order to maintain the intake

air control valve fully closed even during

low-vacuum conditions"

- Question #2, does the vacuum tank even hold vacuum, when positive manifold pressure is acting on it, as it was not designed to handle that? In other words, can the Vacuum switching valve even open or close the valve, under POSITIVE MANIFOLD PSI conditions....

The whole point of this ramble was to inform the general public about whats actually going on inside our plenums when air is being routed about according to the ECU's programming...and that the whole system was never designed to have positive manifold pressure being acted upon it....

I AM NOT BLAMING THE URD MRK-1 IN ANYWAY FOR MY MOTOR FAILING:top:

I switched out for TRD because i was paranoid about it happening again and i hated the power delivery of the Rotrex blowers in general, and knew that it was not going to work with what i wanted to do with my truck...and as far as i can tell, nobody knows for sure if the MRK-1 (or positive mani pressure in general) was the cause of my motors demise... as even the F/I "experts" cant say for sure how much PSI wil cause the manifolds fail (split from sheer PSI)...let alone the ACIS failing from "unusual forces acting on it"

With that being said, i just wanted to let the public know my POV on the subject and leave this thread open for debate on what to do about the ACIS and F/I (non TRD F/I) on our manifolds will do...

The TRD s/c doesn't have this system so this doesn't pertain to the TRD S/C...this should be oblivious as the TRD blower mounts in place of the factory plastic intake...:top: Figure i'd throw that out their...

~~~

Few starter questions for Gadget, as he seems to be on the leading edge of safety s/c these motors. :adore:

1. Have you tried doing dyno runs with the ACIS system open or closed?

2. Can the X-1 or UCON EMS be used to control the ACIS system to BENEFIT the power band of a URD S/C truck?

~~~

Please, lets not turn this into a TRD vs URD debate...this has to do with positive mani pressure in general, on our OEM intake plenums, not about what makes more power or gets your **** sucked faster.... :top: